Address: Zhaobao Village, Yingluo Town, Haicheng City, Liaoning Province

Phone: +86 0412-3270890

Fax:+86 0412-3270198

Email: FQKY@fqky.com

Website: www.fqky.com

Website: en.fqky.com

Mobile phone: +86 13081212999

Mobile phone: +86 15242121616

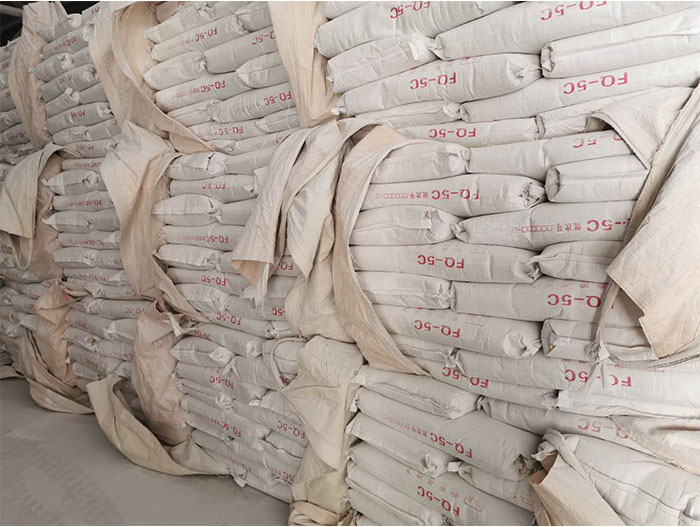

Ultrafine talc is a kind of additive, modifier or filler. It is widely used in many chemical industries. It has a clear strengthening effect in the modification of plastics and rubber. It can improve the tensile strength, impact properties, Creep resistance, heat resistance, tear resistance, etc. It can also improve the appearance of the product, reduce the shrinkage of the product, increase the barrier effect, reduce the air permeability, increase the rigidity and stiffness of the plastic product, has become an important modified material to improve the physical properties of plastic products, and is increasingly favored by the plastic industry . The following is a small introduction to tell you how to distinguish the quality of talcum powder.

The higher the purity of talc, the better the enhancement effect. Other mineral impurities in talc, metal minerals (especially iron) have a very significant impact on the aging resistance of plastics.

The wet whiteness and hue of talc and plastic make the color of the plastic more or less changed. Dark plastic products do not have too high requirements for the whiteness of talc added. However, in order to make the light-colored products have a better color, talc must have a higher wet whiteness and a suitable hue.

The silicon content in talcum powder is an important indicator of talcum powder grade. Talc powder should be selected according to the performance requirements of different plastic products. For example, the silicon content of talc powder added to the film should be higher, the particle size should be smaller, and the particle size distribution should be narrow. Sex and other indicators have improved significantly. However, the silicon content in injection molding, sheet, and rod does not need to be too high. Talc powder with a lower silicon content has a lower price and is rich in resources.

Flowability In the extrusion process, talc is less fluid than other granular inorganic materials, difficult to disperse, and has a large screw torque. Therefore, the use of a better activation aid is the key to overcoming the above problems.

Electrostatic talc has a layered structure with a large specific surface area. The irregular shape of the particles and the convex and concave shapes on the surface make it have a large coefficient of friction and are prone to static electricity. It causes the aggregation of tiny particles and is difficult to disperse.

The above is the method to distinguish the quality of talcum powder. I hope the above method will be helpful to you. If you have any questions, please call us for consultation. We have special staff to answer your questions.

Address: Zhaobao Village, Yingluo Town, Haicheng City, Liaoning Province

Phone: +86 0412-3270890

Fax: +86 0412-3270198

Email: FQKY@fqky.com

Mobile: +86 130-8121-2999 +86 152-4212-1616