Address: Zhaobao Village, Yingluo Town, Haicheng City, Liaoning Province

Phone: +86 0412-3270890

Fax:+86 0412-3270198

Email: FQKY@fqky.com

Website: www.fqky.com

Website: en.fqky.com

Mobile phone: +86 13081212999

Mobile phone: +86 15242121616

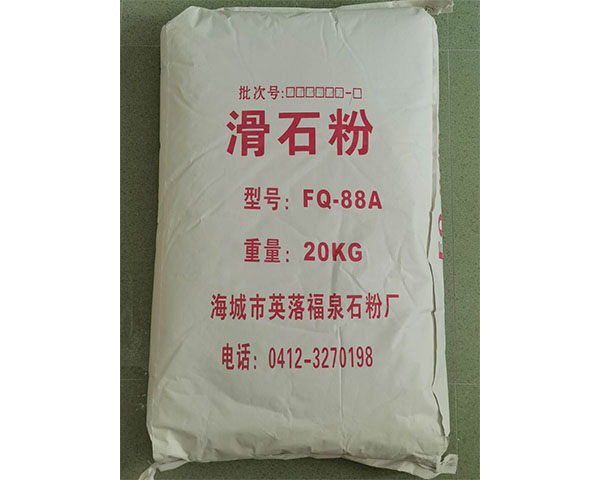

Talcum powder has good suspension and easy dispersibility, and has low corrosivity. In coatings, talc powder can play a role as a filler. Talc manufacturers reduce the manufacturing cost and increase the hardness of the paint film. It also has the characteristics of improving product shape stability, increasing tensile strength, shear strength, compressive strength, reducing deformation, elongation, thermal expansion coefficient, high whiteness, and strong uniform particle size dispersion. The talc powder with flaky particle structure can make the coating film have high water resistance and impermeability of enamel paint. The talc powder with fibrous particle structure can improve the rheology and leveling of the coating, and at the same time it can improve Weatherability of coatings.

Talcum powder is mainly used in primers and intermediate coatings. Talc powder is preferred for many products and flash drying primers and paints for transportation. The primer for steel structures can be used in whole or in part with talc to improve the precipitation of the coating, the mechanical force of the coating film, and the recoatability.

Inorganic fillers play an important role in the modification of plastics and become an indispensable modifier. White talc with a thin sheet structure is an effective reinforcing material in plastics. It can give plastics higher rigidity, creep resistance and better solid gloss under normal temperature and high temperature. The addition of talcum powder can change the various properties of plastics, such as molding shrinkage, surface hardness, flexural modulus, tensile strength, impact strength, thermal deformation temperature, molding process and product dimensional stability. Adding talc to polyethylene and polypropylene plastics can effectively improve the surface hardness and scratch resistance of the product. As we all know, the price of talc is 10% ~ 20% of plastic, so applying talc to plastic not only improves the performance, but also effectively reduces the cost of materials and improves the economic efficiency of the enterprise.

Address: Zhaobao Village, Yingluo Town, Haicheng City, Liaoning Province

Phone: +86 0412-3270890

Fax: +86 0412-3270198

Email: FQKY@fqky.com

Mobile: +86 130-8121-2999 +86 152-4212-1616